Any business, be it large or small must undergo change to remain successful.

Sometimes change means relocating your plant in order to have more room, merging with another company, etc. Plant relocations are a big deal and can take a lot of time and energy.

To make the experience a little less stressful here are 4 simple yet effective tips

1. Determine the value of all the equipment

This information is required for insurance purposes, border crossings and legal reasons. The necessary paperwork can be assembled with the help of your accounting department.

Also, if you’re crossing borders you should choose a plant relocation specialist who has a good working relationship with a reputable customs broker. This is because the process can be expedited with the help of a good customs broker, particularly when dealing with equipment that’s been purchased at auction or is brand new from an overseas manufacturer.

“Countries of origin” is a phrase you’ll hear a lot. That’s important information that everyone needs to know. You’ll also need it in the paperwork. A seasoned broker can help navigate this process easily.

2. Determine UL listings/requirements for all equipment

Think about the location you’re moving your plant to. Make sure you check out what UL inspections/requirements the local municipality mandates. Does all your equipment pass muster?

There have been many situations where companies have equipment going from one country to another and that equipment did not meet local UL electrical standards. This not only results in unwanted trouble, but also in downed production and lost revenue.

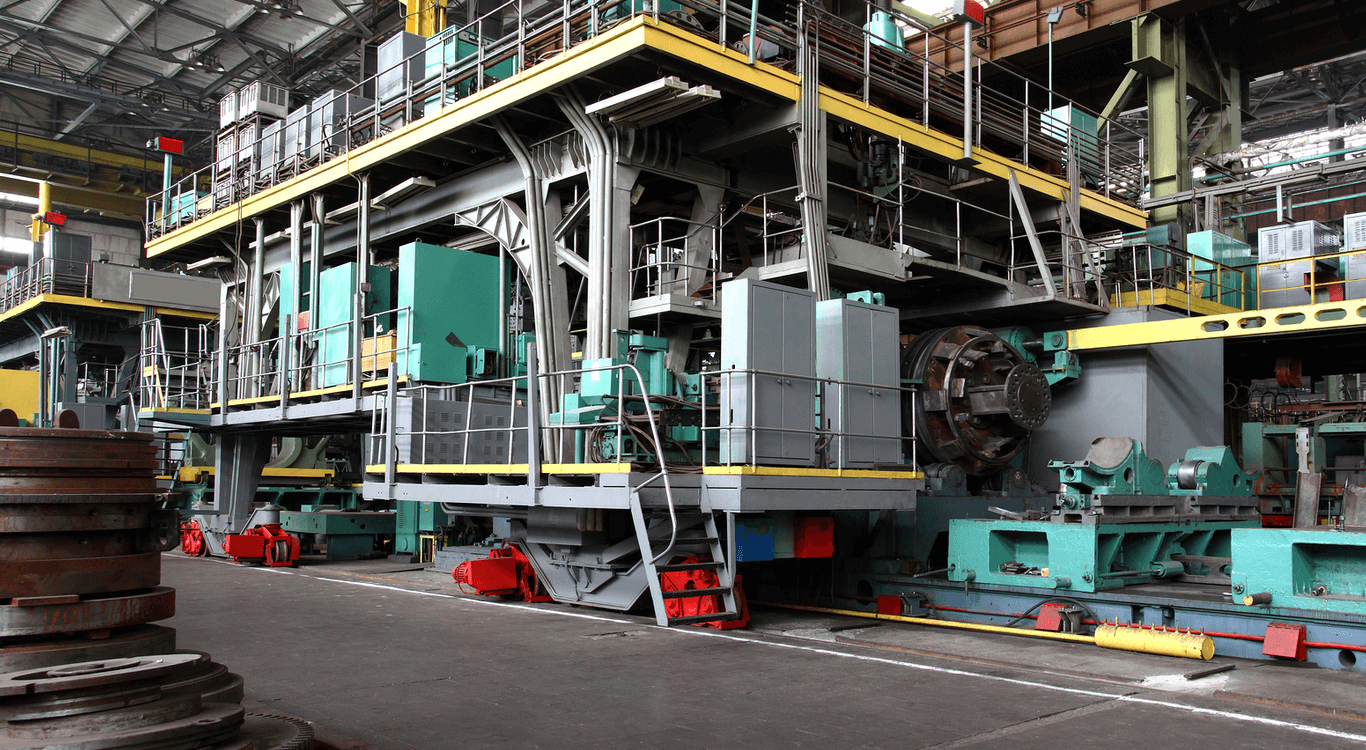

3. Inspect the condition of each piece of equipment

Inspect the condition of each piece of equipment in your plant before you move anything. Look for any signs of extreme rust, deterioration, or cracked casings in the machinery.

You may want to consider leaving behind any piece of equipment that is severely damaged and replacing it with a new one. While this may seem expensive, it could cost you more money if something breaks while it is being transported. If a hydraulic shaft falls off, it could seriously injure one of your workers while moving it or could hit a nearby machine.

Also, it’s easy to neglect the need for new machinery because you don’t want to lose quality working days. By doing it during a plant relocation can save time. You can ask for the new machine to be delivered to the new address. Plus, you may already be losing a few days of work because of the relocation, so you can kill two birds with one stone.

4. Check the dimensions and weight of all machinery/components

This might seem straightforward, but your plant relocation specialist needs precise numbers, not estimates.

This information determines how your equipment is transported. Different methods will have to be applied to different equipment —and sometimes a combination of methods.

Make sure you have enough space at the new plant for everything you want to take, once you have decided on which machinery will be moved. This can be done by measuring both the square footage of the factory to which the machines will be going and the equipment itself.

Do not just measure the base when measuring each piece of equipment. You also need to allow for any part, wires, or vents that are sticking out from around the machine. Also, to ensure you have enough ceiling space so that it does not scrape the top of the equipment measure the height. Your move agent usually helps out with this.

Moving plants and machinery to a new location is a complex process. If not handled with care, it can cause serious damage to the machines and great loss to your business.

Due to the complexities involved in relocating a plant, it is prudent to select a moving service provider with experience in moving plant and machinery.

Writer Relocations has been helping businesses move plants and machinery without stress or damage for over 60 years now. We are one of India’s oldest and most trusted moving agency. With an excellent track record of executing damage-free commercial moves, you can easily trust Writer Relocations for your next move.

Don’t just take our word for it. Read what people like you say about packing and moving with Writer Relocations.

“The Writer Relocations team completed more than 2,25,000 man hours of work with Shell, without any major incident, or loss of time.

They also met the agreed timelines in each phase. During the whole move with Shell, chemicals and equipment worth millions of dollars were moved. They covered more than 25,000 kms across two sites of Shell.”

-Dharmesh Kumar, Shell

Also check out our case studies for commercial relocations.

Writer Relocations is accredited with the best moving associations, known for their international service quality standards, globally. When you move with Writer Relocations, you can rest assured that you are moving with the best in the business.

Get a FREE moving quote by Writer Relocations for your plants and machinery move. Or contact us on our toll-free number for India, @ 022-334-91787.

Found this article useful? Like and share this with your friends on social media. Or email it to a friend who might find it helpful.